What Materials Can You Cut or Engrave with a Laser Machine?

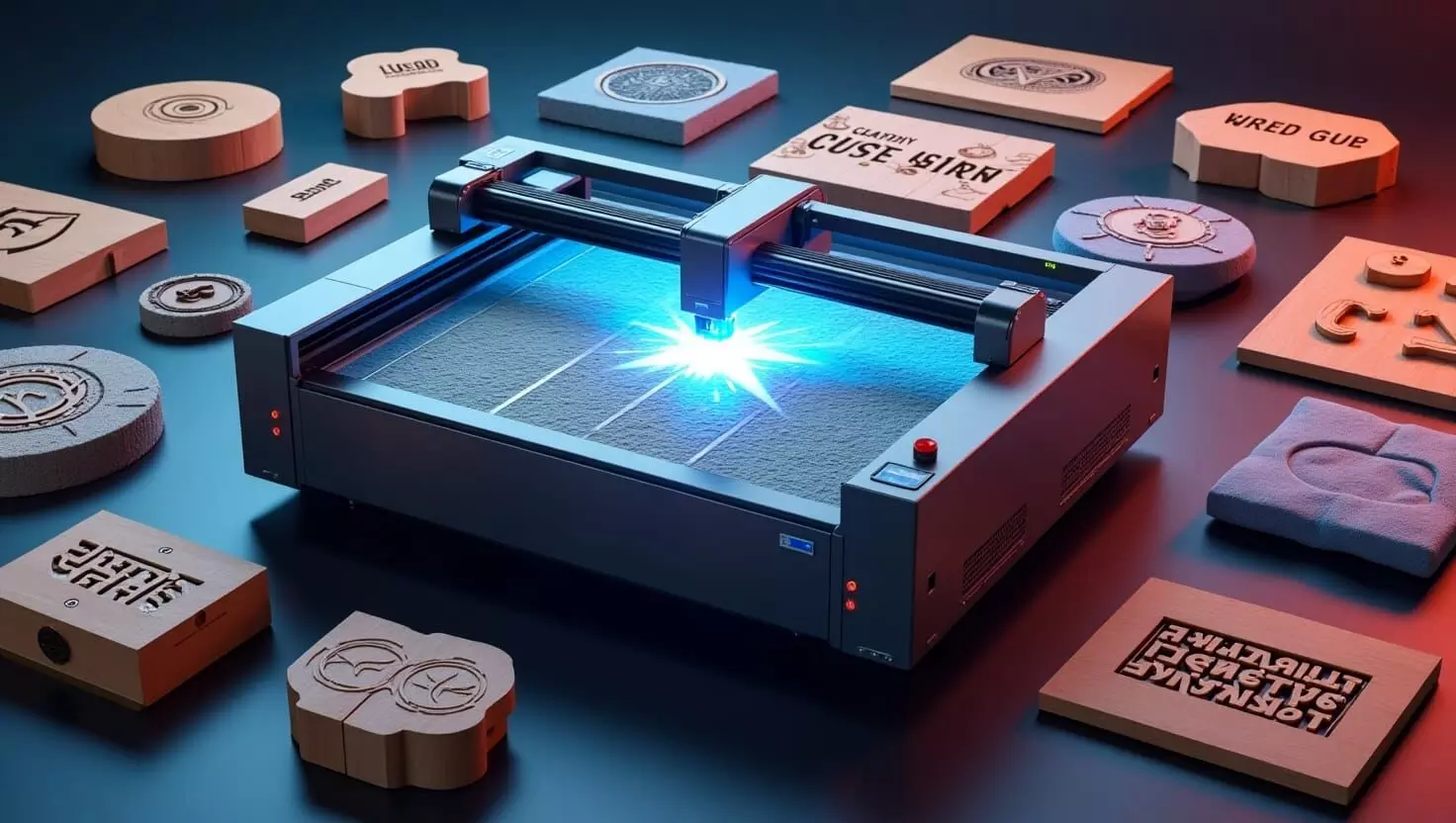

image for illustrative purpose

Laser machines are powerful tools capable of shaping a diverse array of materials with unmatched precision. However, each material behaves differently under laser energy due to its composition, thickness, and thermal properties. Selecting the right material and optimizing machine settings are crucial for achieving clean, safe, and effective results.

Let’s explore some of the most common materials used in laser cutting and engraving, along with specific laser compatibility and performance insights.

7 Common Materials You Can Cut with a Laser Machine

Laser machines are powerful tools capable of shaping a diverse array of materials with unmatched precision.Here’s a breakdown of seven commonly used materials that work well with laser machines. So let's get started.

1. Acrylic (PMMA)

Acrylic is a clear thermoplastic praised for its strength, clarity, and rigidity. Available in both cast and extruded forms, it reacts particularly well to CO₂ and diode-pumped lasers. Cast acrylic is preferred for engraving due to its frosty finish, while extruded sheets may require slower cutting speeds to reduce stress cracking.

Acrylic emits toxic fumes when vaporized, so proper ventilation is essential. Lower laser power yields smoother results, while excessive power can lead to scorching. For example, an 80W CO₂ laser can cut 8 mm thick acrylic at 5 mm/s, producing clean, polished edges with minimal thermal damage. Blower settings should be carefully balanced, too strong and the edges may turn rough; optimal pressure feels like a firm breeze on the skin during setup.

2. Plywood

Plywood consists of layered wood veneers bonded with adhesives, making it laser-cuttable across its many varieties. Due to the resins used in lamination, adequate fume extraction is necessary.

This material demands relatively high power and fast speeds for repeat cuts. Strong airflow ensures cleaner edges and supports increased feed rates. CO₂ lasers are most commonly used, though fiber lasers can also perform well depending on the setup.

3. Cardboard

Cardboard is a lightweight, low-cost material commonly used for prototyping, displays, and packaging. It is compatible with all laser types and cuts easily at moderate power and high feed speeds.

Though not significantly toxic, cardboard does produce combustion byproducts. Maintain airflow for safety, but keep blower pressure low to avoid lifting the material mid-cut. When properly configured, cardboard cuts cleanly with minimal kerf or thermal discoloration.

4. Foam

Foam materials vary widely in composition and structure, encompassing materials like expanded polystyrene, EVA foam, and Depron modeling foam. Some foams cut well, while others are unsuitable due to toxicity or melting. CO₂ laser machines are often used for precision cutting, but foam type and composition should always be verified before use.

Low power, high speed, and excellent ventilation are essential. Toxic gases are often released, so a mask is recommended. Lightweight foams also require minimal blower pressure to prevent lifting. When used carefully, machines such as the Nova and Odin series from Thunder Laser USA can handle a wide range of materials, including foam, with excellent results.

5. Metals

Laser cutting of metals typically requires high-power systems. Fiber and solid-state lasers perform best for metals, although some CO₂ lasers can cut thin metal sheets.

Two cutting techniques are used:

- Reactive cutting: Suitable for carbon steel and titanium; uses oxygen to support oxidation-assisted cutting.

- Fusion cutting: Common for stainless steel, copper, and aluminum; utilizes inert gases like nitrogen and argon to remove molten material.

Metals produce little toxic residue but still require standard safety precautions.

6. Plastics

Plastics cover a wide range of materials with varying laser compatibility. Safe choices include:

- Polyimide (Kapton®) is excellent for diode lasers

- Polyester (Mylar®) performs well with CO₂ lasers

Polycarbonate should be avoided except in very thin sheets (1 mm or less) as it yellows and distorts under heat. Polystyrene cuts cleanly but releases hazardous fumes. Since all plastics emit some toxic byproducts, ventilation and protective gear are non-negotiable.

7. Textiles

Natural fabrics like cotton, silk, and wool cut beautifully with low to moderate power and high feed speeds. Use minimal blower pressure to avoid movement. Synthetic fabrics can melt or ignite easily, so finding optimal settings through testing is essential. Once dialed in, synthetics yield sharp, consistent results.

Recommended Laser Settings for Popular Materials

Use the table below as a quick-reference guide for setting your laser machine parameters according to the material type. These ranges are starting points—always test settings on a small sample before full production.

Conclusion

Laser cutting and engraving offer a flexible and high-precision method for working with a wide variety of materials. Each material comes with its unique set of properties, requiring specific machine power, speed, and ventilation strategies to ensure safety and quality.

Understanding the thermal behavior, fume output, and reaction to specific laser types will not only extend the life of your machine but also elevate the finish of your projects. As with any process involving heat and fumes, safety must remain your top priority, so always test settings on scrap, use proper fume extraction, and wear appropriate protective gear.

By combining technical knowledge with experimentation, even experienced makers can continue to unlock new creative possibilities with laser cutting and engraving.