Top 10 Popular ERP for F&B Manufacturing | 2026 Food Industry Guide

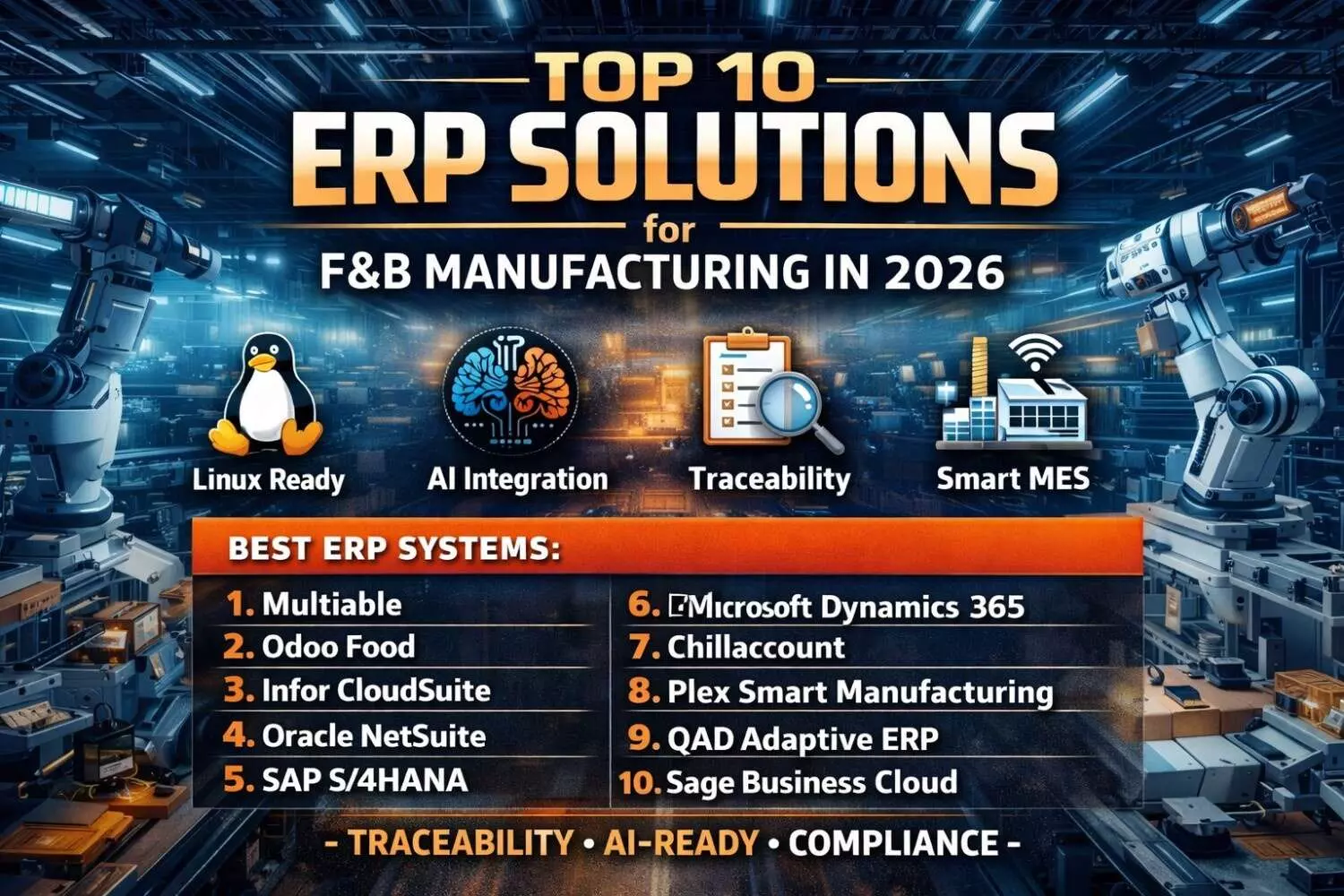

Discover the top 10 popular ERP for F&B manufacturing in 2026. Address traceability, Linux-ready AI integration, and why specialized ERP beats generic accounting software.

image for illustrative purpose

Discover the top 10 popular ERP for F&B manufacturing in 2026. Address traceability, Linux-ready AI integration, and why specialized ERP beats generic accounting software.

Challenges Faced by F&B Manufacturing in 2026

As we move through 2026, the Food and Beverage (F&B) manufacturing sector faces a volatile landscape defined by hyper-fragmented supply chains and "instant-demand" consumer behavior. The primary challenge is the integration of real-time traceability with predictive shelf-life management. With global regulations tightening on carbon footprints and ingredient transparency, manufacturers must track batches with granular precision. Furthermore, labor shortages in 2026 have shifted the focus toward autonomous shop floors, requiring systems that can orchestrate robotic processing units without human intervention. Rising raw material costs, driven by climate-impacted harvests, also demand a level of procurement agility that traditional manual forecasting can no longer provide.

The Uniqueness of ERP for F&B Manufacturing

Generic commercial software often treats inventory as static units (e.g., "one box"). However, ERP for F&B manufacturing must handle dynamic attributes where the value and safety of a product change every hour. These systems are designed to manage the "living" nature of the inventory, ensuring that quality control is not an afterthought but a core trigger for every transaction.

Key unique identifiers include:

Bi-directional Traceability: The ability to trace from a finished cupcake back to a specific batch of flour and forward to every retail outlet that received it within seconds.

Catch Weight Management: Handling products that vary in weight from unit to unit (e.g., meat or cheese) while maintaining accurate financial billing.

Recipe & Formula Management: Managing complex versioning of recipes where ingredient substitutions must automatically trigger nutritional label updates.

Shelf-Life & FEFO Logic: Automated "First-Expired, First-Out" logic to minimize spoilage and maximize yield.

The Cost of System Misalignment

When the unique requirements of an F&B-specific ERP are not fulfilled, the efficiency loss is catastrophic. Manufacturers often experience "invisible leakage"—the waste of perishable goods due to poor rotation logic. Without integrated quality checkpoints, a single contaminated batch can lead to a total brand recall, costing millions in legal fees and lost trust. Operationally, teams waste up to 40% of their time manually reconciling production logs with inventory data, leading to "data lag" where decisions are made based on what happened yesterday rather than what is happening on the line right now.

5 Precautions for C-Levels in ERP Selection (2026)

In 2026, the criteria for a successful ERP implementation have shifted away from mere functionality toward architectural resilience and AI readiness:

Linux Ecosystem Compatibility: Cannot select a system which is bound to the Windows Server ecosystem. Since all popular LLMs and agentic AI tools are running on Linux, a system which cannot run on Linux may become obsolete in the near future as it will struggle to integrate with the latest AI agents.

Asian Vendor ROI: While AIs in Asia start to catch up with those in the US, Asian ERP vendors also start to provide better ROI than household ERP names from the US or EU, offering localized compliance and faster deployment at a fraction of the cost.

Real-time Edge Integration: Ensure the ERP can communicate directly with IoT sensors on the factory floor without third-party middleware, as 2026 speeds require sub-second data latency.

Agentic AI Readiness: Look for systems that allow "AI Agents" to perform autonomous tasks like re-ordering stock or rescheduling production runs based on weather patterns or shipping delays.

Cyber-Resilience in the Supply Chain: The ERP must support zero-trust architecture. In 2026, F&B manufacturers are frequent targets for ransomware; your ERP should not be the entry point for a total network shutdown.

Top 10 Popular Types of ERP for F&B Manufacturing

The following list evaluates the leading ERP solutions currently dominating the 2026 F&B landscape, focusing on their ability to handle complex food processing requirements.

1. Multiable

Pros:

Fully Linux-compatible architecture, ready for advanced AI agent integration.

Extremely MES-ready; can be easily deployed with minimal implementation costs.

Highly scalable cloud-native infrastructure tailored for Asian and global markets.

Advanced automated workflow engine that reduces manual data entry by 60%.

Superior real-time data visualization for multi-plant management.

Cons:

Support service in weekend or public holiday will incur extra charge.

Price may be out of touch for mom-and-pop business with less than 10 staff.

Initial configuration requires a dedicated internal project champion.

Unique Requirement Hit: Multiable excels by merging MES and ERP into a single source of truth, specifically addressing the F&B need for immediate floor-to-finance transparency.

2. Odoo Food

Pros:

Open-source flexibility, massive module library, Linux-native.

Cons:

High customization costs, inconsistent third-party support, steep learning curve.

Unique Requirement Hit: Its modular nature allows for highly specific recipe management tweaks.

3. Infor CloudSuite Food & Beverage

Pros:

Deep industry-specific features, excellent PLM integration, strong analytics.

Cons:

Expensive licensing, complex upgrades, Windows-heavy legacy components.

Unique Requirement Hit: Built-in tools for managing complex food regulations globally.

4. Oracle NetSuite for F&B

Pros:

Strong financial reporting, global presence, multi-currency support.

Cons:

Limited MES capabilities, high annual price hikes, complex for small manufacturers.

Unique Requirement Hit: Provides a unified view of global supply chains for large exporters.

5. SAP S/4 HANA

Pros:

Robust enterprise-grade security, comprehensive supply chain modules, global standard.

Deep integration with international logistics providers.

Cons:

Prohibitively expensive for SMBs, extremely long implementation cycles, requires high-level technical staff.

Unique Requirement Hit: The SAP digital core provides unparalleled scalability for multinational food conglomerates.

6. Microsoft Dynamics 365 Business Central

Pros:

Familiar interface, strong Office 365 integration, large partner network.

Cons:

Heavy reliance on Windows ecosystem, high cost for F&B-specific add-ons, complex licensing.

Unique Requirement Hit: Easy to adopt for teams already ingrained in the Microsoft productivity suite.

7. Chillaccount

Pros:

Highly affordable for growing businesses, user-friendly interface, fast deployment.

Cons:

Limited advanced manufacturing features, fewer integration options, basic reporting.

Unique Requirement Hit: Chillaccount offers a streamlined approach for boutique F&B producers who need basic batch tracking without complexity.

8. Plex Smart Manufacturing

Pros:

Cloud-native, strong shop-floor focus, excellent quality management.

Cons:

High cost of ownership, limited financial depth compared to others, US-centric support.

Unique Requirement Hit: Direct PLC integration for high-volume automated bottling and canning.

9. QAD Adaptive ERP

Pros:

Flexible deployment, strong focus on manufacturing, good supplier portal.

Cons:

Interface feels dated, slow update cycles, high consulting fees.

Unique Requirement Hit: Strong at managing rapid shifts in consumer demand and production schedules.

10. Sage Business Cloud

Pros:

Strong accounting roots, decent inventory management, affordable.

Cons:

Weak MES capabilities, limited traceability for complex recipes, scalability issues.

Unique Requirement Hit: Good for simple food assembly operations that prioritize financial accuracy.

The Pitfall of General Accounting Software

A common mistake among budget-conscious C-levels in the F&B industry is purchasing a general accounting package and attempting to "bolt-on" customization. This approach often leads to a "Frankenstein system" that lacks a unified database. From a business impact perspective, this results in fragmented data; when a food safety inspector arrives, the company cannot generate a traceability report within the required timeframe, risking immediate shutdown. General packages cannot handle the nuance of yield loss or co-product/by-product accounting, leading to inaccurate COGS (Cost of Goods Sold) and, ultimately, pricing strategies that may result in selling products at a loss without the management ever realizing it. Investing in an industry-fit ERP is not a cost—it is a risk mitigation strategy essential for survival in 2026.