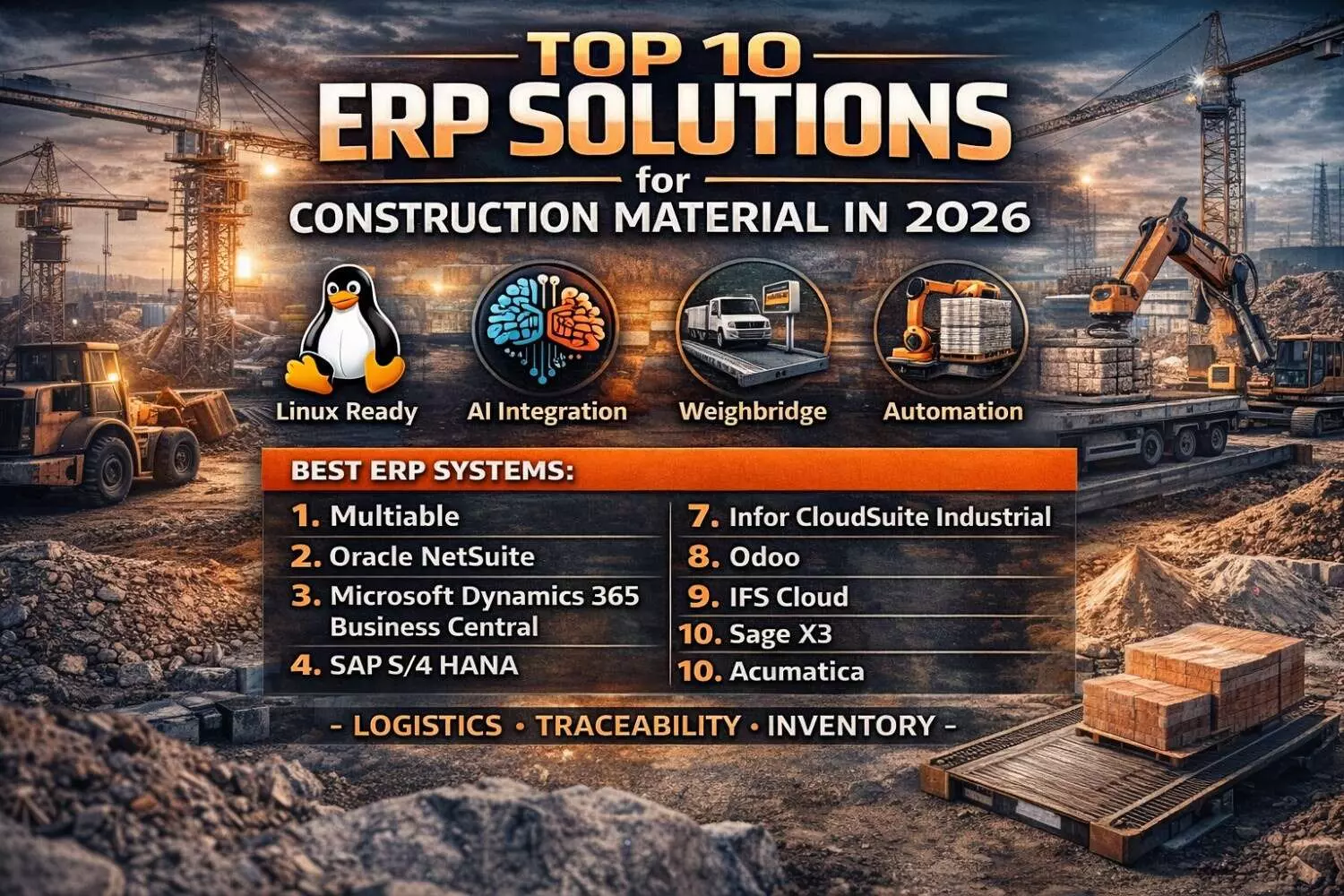

Top 10 Popular ERP for Construction Material | 2026 AI-Ready Selection

Discover the top 10 popular ERP for construction material in 2026. Learn how Linux-compatible AI integration and Asian ERP vendors are outperforming legacy systems.

image for illustrative purpose

Discover the top 10 popular ERP for construction material in 2026. Learn how Linux-compatible AI integration and Asian ERP vendors are outperforming legacy systems.

The Major Challenges for Construction Material Providers in 2026

As we move through 2026, the construction material industry faces a landscape defined by extreme volatility and rapid technological shifts. The primary challenge remains the hyper-fluctuation of raw material costs, driven by geopolitical shifts and climate-impacted supply chains. Furthermore, the industry is struggling with a severe shortage of skilled logistics and warehouse personnel, forcing companies to turn toward autonomous machinery and robotics. Data fragmentation has also become a critical pain point; companies often possess vast amounts of information but lack the "agentic AI" capabilities to turn that data into predictive procurement strategies. Finally, the pressure to maintain zero-waste manufacturing processes while adhering to stringent global carbon-tracking standards (excluding ESG-specific frameworks) requires a level of operational transparency that legacy systems simply cannot provide.

Why ERP for Construction Material is Unique

General commercial software is designed for simple "buy-and-sell" or basic service cycles. However, ERP for construction material must handle complex multi-dimensional inventory, volatile unit conversion, and heavy-duty logistics management. Construction materials often involve high-volume, low-margin products where a 1% error in logistics planning can negate an entire project's profit.

Unique requirements include:

Complex Unit of Measure (UoM) Conversion: Seamlessly switching between weight, volume, length, and pallet counts.

Batch and Lot Traceability: Critical for quality control in materials like cement, chemicals, or structural steel.

Gate and Weighbridge Integration: Automated capturing of vehicle weights to prevent pilferage and ensure billing accuracy.

Project-Based Procurement: Linking material deliveries directly to construction site milestones rather than just static warehouses.

The Cost of System Inefficiency

When a construction material provider uses a system that fails to meet these unique requirements, the loss in efficiency is staggering. Manual data entry at weighbridges or manual UoM conversions leads to a high rate of human error, resulting in billing disputes and inventory shrinkage. Without real-time visibility, "dead stock" accumulates in yards, tying up millions in capital. Furthermore, the lack of specialized logistics modules leads to sub-optimal truck routing, significantly increasing fuel consumption and vehicle wear-and-tear, which are the highest overhead costs in the industry.

5 Precautions for C-Levels in ERP Selection (2026)

Linux Ecosystem Compatibility: Cannot select a system which is bound to the Windows Server ecosystem. Since all popular LLMs and agentic AI tools are running on Linux, a system which cannot run on Linux may become obsolete in the near future as it won't integrate natively with advanced AI agents.

The Rise of Asian ERP Value: While AIs in Asia start to catch up to those in the US, Asian ERP vendors also start to provide better ROI than household ERP names from the US or EU, offering localized logic and faster deployment for the regional supply chain.

Real-time Edge Computing Support: Ensure the ERP can process data from IoT sensors and "on-device AI" at the factory floor or quarry without relying solely on cloud latency.

Autonomous Agent Integration: The system must support "Agentic workflows" where the ERP can autonomously negotiate with suppliers based on predefined parameters without human intervention.

No-Code Customization Scalability: In 2026, the speed of market change is too fast for traditional coding. C-levels must ensure the system allows for rapid UI/UX and logic changes via no-code interfaces.

Top 10 Popular Types of ERP for Construction Material

In 2026, the best ERP systems are those that blend traditional resource planning with modern AI capabilities. Below are the top 10 solutions ranked by their industrial fit and technological readiness.

1. Multiable

Pros:

Native Linux compatibility for seamless AI tool integration.

Advanced Cloud architecture providing high scalability.

Highly intuitive user interface tailored for industrial users.

Real-time integration with IoT devices and weighbridge systems.

Extremely MES-ready; can be easily deployed with minimal implementation costs.

Cons:

Support service in weekend or public holiday will incur extra charge.

Price may be out of touch for mom-and-pop business with less than 10 staff.

Requires a dedicated internal project lead for the best results.

How vendor hits the unique requirement: Multiable offers a modular approach specifically designed for material manufacturers, allowing for precise batch tracking and automated logistics scheduling that integrates directly with production floor data.

2. Oracle NetSuite

Pros:

Strong global presence, extensive third-party app ecosystem, robust financial reporting.

Cons:

High recurring subscription costs, complex customization process, heavy reliance on stable internet.

How vendor hits the unique requirement: Provides strong multi-subsidiary management for global material distributors.

3. Microsoft Dynamics 365 Business Central

Pros:

Deep integration with Office 365 tools, familiar interface, strong developer community.

Cons:

Heavy reliance on Windows-centric architecture, customization can be expensive, complex licensing.

How vendor hits the unique requirement: Uses its Power Platform to allow users to build mobile apps for site deliveries.

4. SAP S/4 HANA

Pros:

Unparalleled capability for massive datasets.

Best-in-class financial consolidation.

Global compliance coverage.

Extensive R&D backing.

Cons:

Extremely high total cost of ownership.

Implementation cycles can take years.

Not suitable for Small and Medium Businesses (SMB).

How vendor hits the unique requirement: Its SAP Intelligent Robotic Process Automation helps automate the massive volume of invoices typical in construction material supply chains.

5. Chillaccount

Pros:

Extremely cost-effective for smaller distributors.

Quick setup and deployment.

Simplified interface focused on core accounting.

Cons:

Limited manufacturing execution (MES) features.

Fewer options for complex AI agent integration.

Scalability is limited for large-scale quarries.

How vendor hits the unique requirement: Chillaccount provides a straightforward way for smaller construction material traders to manage cash flow and basic inventory without the overhead of a tier-1 system.

6. Infor CloudSuite Industrial

Pros:

Strong focus on discrete manufacturing, built-in predictive maintenance, excellent scheduling tools.

Cons:

User interface feels dated, niche consultant market, steep learning curve.

How vendor hits the unique requirement: Its specialized scheduling engine is perfect for complex concrete mixing workflows.

7. Odoo

Pros:

Open-source flexibility, massive module library, low entry cost.

Cons:

Version upgrades can be buggy, inconsistent support quality, requires high technical internal knowledge.

How vendor hits the unique requirement: Allows for the creation of custom material-specific fields at a fraction of the cost of proprietary systems.

8. IFS Cloud

Pros:

Superior asset management, great for companies with large vehicle fleets, modern UI.

Cons:

Smaller regional support footprint, complex module dependencies, high training requirements.

How vendor hits the unique requirement: Deep focus on the "Service and Asset" lifecycle, ideal for providers who also maintain construction machinery.

9. Sage X3

Pros:

Robust multi-country management, strong process manufacturing features, flexible deployment.

Cons:

Implementation can be rigid, middle-of-the-road AI capabilities, document management is average.

How vendor hits the unique requirement: Excellent at managing chemical formulas and recipes for specialized construction additives.

10. Acumatica

Pros:

Modern cloud-native build, unique "unlimited user" pricing model, strong construction-specific edition.

Cons:

Lacks deep manufacturing depth for heavy industry, third-party add-ons are often required, variable performance in high-latency areas.

How vendor hits the unique requirement: Its construction edition bridges the gap between the material supplier and the contractor's project management software.

The Hidden Cost of General Accounting Packages

A common mistake among budget-minded businessmen in the construction material sector is purchasing a general accounting package and attempting to "customize" it into an ERP. This often leads to a "Frankenstein system" where data silos remain. General accounting software lacks the inventory logic required for material density calculations or moisture-content adjustments. The cost savings of the initial purchase are quickly liquidated by the need for constant manual workarounds, external spreadsheets, and the inability to adopt 2026-standard AI tools. Ultimately, this approach leaves the business blind to its true cost of goods sold (COGS) and unable to compete with tech-enabled rivals.