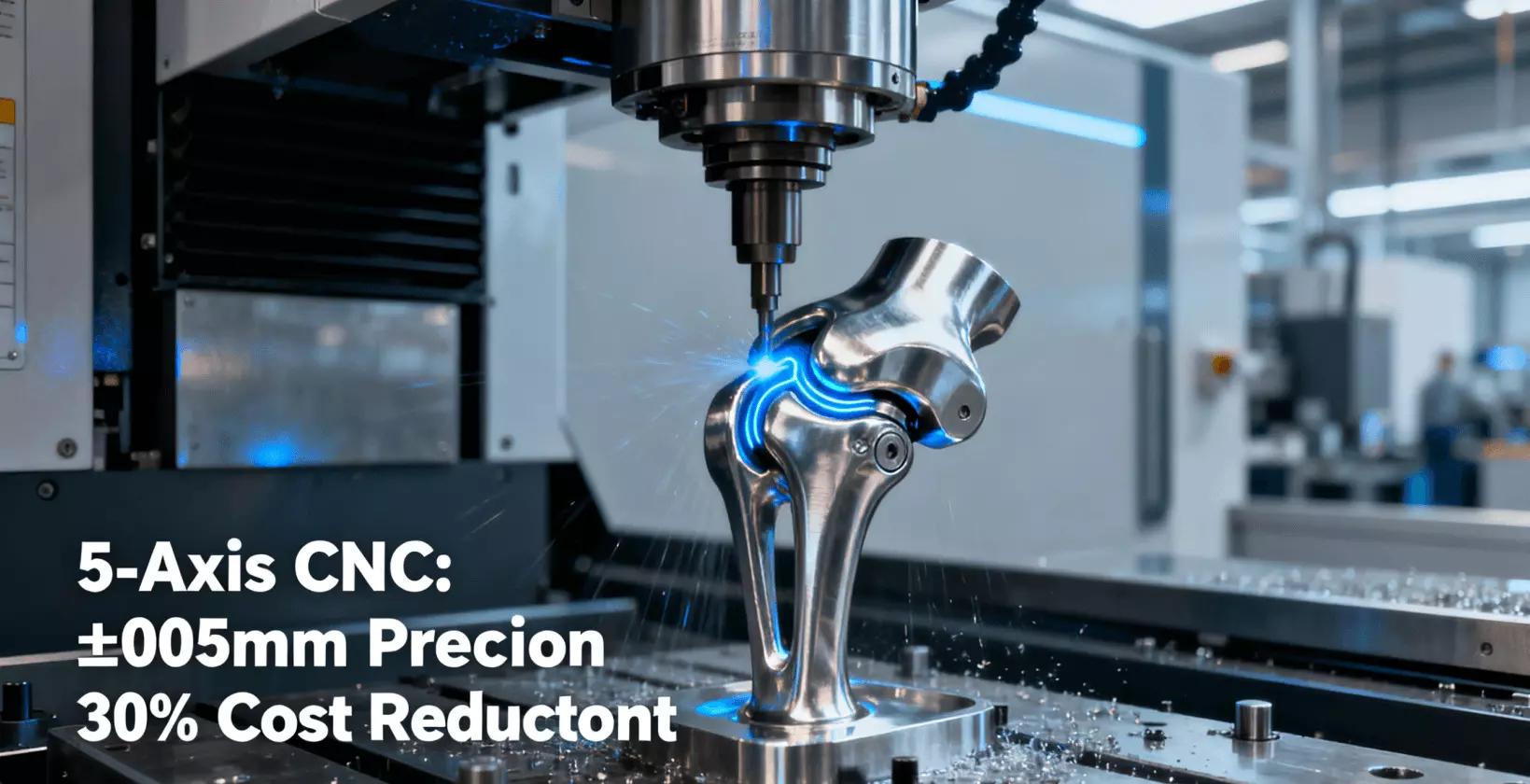

How 5-Axis CNC Machining Reduces Medical Device Prototyping Costs by 30% While Meeting ISO 13485 Standards

Discover how 5-axis CNC technology achieves ±0.005mm precision for medical prototypes like surgical guides & implants while reducing costs and ensuring ISO 13485 compliance. Explore technical insights and supply chain strategies.

image for illustrative purpose

Introduction

Medical device engineers face the challenge of manufacturing complex components like surgical guides and implants, which require high precision, superior surface finishes, and biocompatibility. Traditional 3-axis or 4-axis CNC machining often leads to alignment errors and extended lead times. In contrast, 5-axis CNC machining provides a transformative solution, enabling higher precision (±0.005mm), reducing costs by up to 30%, and meeting stringent standards such as ISO 13485 in prototyping and low-volume production.

How Does 5-Axis CNC Machining Achieve ±0.005mm Precision for Medical Device Prototypes?

In medical device manufacturing, precision is an unquestionable baseline. 5-axis CNC machining meets this demand through advanced technological integration.

Technical Principles and Precision Assurance Mechanisms

Figure 2: Visual explanation of how 5-axis CNC with RTCP eliminates cumulative errors by machining multiple part faces in a single setup, unlike 3-axis machining.

The core of 5-axis CNC machining precision lies in the RTCP (Rotational Tool Center Point) function. Unlike 3-axis systems that require physical repositioning of the workpiece, RTCP allows the machine's controller to dynamically compensate the tool tip position in real-time as the rotational axes move. This eliminates geometric errors introduced by repeated repositioning and fixturing. According to research on multi-axis machining accuracy by the National Institute of Standards and Technology (NIST), this dynamic compensation is crucial for achieving micron-level tolerances on complex part geometries. This capability is fundamental to the reliability of modern 5-axis CNC machining centers.

- Practical Application in Thin-Wall Structure Machining

Consider the case of machining an aluminum surgical guide with a 0.5mm thin-wall structure. A 3-axis CNC struggles with such a part, requiring multiple setups that increase the risk of error and deformation. With 5-axis CNC, the part can be completed in a single setup. The tool maintains the optimal orientation relative to the workpiece surface, ensuring uniform cutting forces. The result is a perfectly formed thin wall with a surface roughness of Ra < 0.8μm.

- The Critical Role of Quality Systems

The whole procedure is performed under a certified quality system like ISO 9001, which guarantees the stability and repeatability necessary for every medical device prototype. It is imperative for medical suppliers to have ISO 13485 certification, which ensures uniformity from the design stage to the finished product in the whole field.

Why Should Cost-Sensitive Medical Projects Choose Chinese 5-Axis CNC Services?

For medical startups and OEMs, controlling prototyping costs without sacrificing quality is paramount. Chinese 5-axis CNC machining services offer a compelling value proposition.

In-Depth Analysis of Cost Advantages

The primary driver of cost-effectiveness is economies of scale. Chinese suppliers operate large clusters of advanced machine tools, significantly reducing the unit hour cost. According to The Economist's global manufacturing cost analysis, China maintains a significant advantage in operational expenditures. This is directly reflected in the price of 5-axis CNC machined components. For example, the price difference for a complex aluminum housing part can be up to 35% when comparing quotes from European manufacturers and those in Eastern China, making Chinese services highly attractive for low-volume production.

Cross-Industry Application of Quality Standards

Cost-effectiveness does not come at the expense of quality. Leading Chinese precision machining workshops often hold stringent certifications from industries like aerospace, such as AS9100D. This standard's rigorous focus on traceability and defect prevention is directly applicable to medical manufacturing, fostering a quality culture that exceeds basic requirements. When seeking Chinese 5-axis CNC machining services, identifying suppliers with such cross-industry certifications is a marker of superior precision CNC machining capabilities.

What are the Key Factors for UK Medical Device Manufacturers in Selecting 5-Axis CNC Services?

For UK manufacturers, post-Brexit supply chain dynamics make supplier selection more critical. A hybrid model leveraging both local expertise and Asian technical capabilities is often the optimal choice.

New Model of Supply Chain Collaboration

A successful strategy involves partnering with UK-based 5-axis CNC machining services providers that have strong technical partnerships with Chinese factories. This model combines local project management and rapid response with cost-effective, technologically advanced manufacturing. For instance, a UK team collaborated with a Chinese factory to deliver a functional orthopedic implant prototype within 48 hours, demonstrating seamless collaboration.

- Four-Dimensional Evaluation System

Selecting the right partner requires a multi-dimensional assessment:

1. Technical Verification:

Confirm the supplier's machines possess genuine RTCP functionality.

2. Medical Certification:

The supplier must have the essential ISO 13485 certification for medical device manufacturing.

3. Material Traceability:

The supplier must provide complete documentation for material sourcing.

4. Design Feedback Responsiveness:

The partner should provide proactive custom part solutions and Design for Manufacturability (DFM) analysis to optimize designs.

Advantages of Localized Services

It is advisable for UK firms that are in the quest of good, reliable and top-class aluminum 5-axis CNC components to opt for a supplier with a strong reputation and wide certifications (among which AS9100D and ISO 13485). As an example, the partner network of a supplier in the UK can offer convenient and quick 5-axis CNC machining services UK.

How to Optimize the Design of Complex Medical Devices for 5-Axis CNC Machining?

To fully leverage the advantages of 5-axis technology, designs must be optimized for the process. Effective Design for Manufacturability (DFM) is key.

Important Principles for Design Optimization

For 5-axis CNC machined parts, key parameters include maintaining a minimum wall thickness of 0.3mm and designing continuous surfaces with transition angles greater than 30 degrees. These guidelines prevent tool vibration and ensure structural integrity during machining. Using advanced CAM software allows engineers to simulate the entire process, predict cutting force distribution, and thus avoid thin-wall deformation before any material is cut. For a practical demonstration of the workflow from 3D model to finished product, such as an endoscope housing, refer to detailed case studies on 5-axis CNC machining services.

Can Low-Volume Production Benefit from the Economics of 5-Axis CNC Machining?

5-axis CNC is not only suitable for mass production; it offers significant economic advantages for low-volume production (50-500 pieces).

Cost Model for Low-Volume Production

The economics become favorable for low volumes. While 3-axis machining requires designing and manufacturing multiple custom fixtures, a 5-axis machine typically needs only one. This eliminates fixture costs and reduces changeover time between jobs. Studies show that for batches under 500 pieces, the per-unit cost using 5-axis machining can be 22% lower than with 3-axis machining, making it an excellent choice for pilot production and custom part solutions.

Value of Part Consolidation

A major advantage is part consolidation. An assembly like a respiratory valve, traditionally composed of 10 separate components, can be redesigned as a single, complex 5-axis CNC machined part. This not only improves reliability by eliminating inter-part tolerances but also reduces assembly costs by 40%. Quality systems like IATF 16949, known for its Production Part Approval Process (PPAP), provide a robust framework for ensuring consistency in such medical low-volume production.

Conclusion

To wrap it up, 5-axis CNC technology can be considered as the medical prototype implementing the technology of integrated machining, and dynamic precision compensation, and optimized global supply chain collaboration, that has the ability of giving 30% cost reduction while still being within the medical standards.

In case you are looking for personalized prototyping approaches, that would still be MRI compliant for your medical device project, sending your drafts to a professional platform, like JS Precision is a smart move. You will be able to receive real-time quotes and detailed Design for Manufacturability (DFM) analysis while getting to know the ways in which the technology can bring value to your project.

Author Bio

The author of this article is a precision manufacturing analyst focused on the aerospace and medical device manufacturing sectors. He has long researched key technologies such as 5-axis simultaneous CNC machining, in terms of academia-industry integration, he is committed to sharing practical insights in high-end equipment manufacturing, providing the industry with technically valuable analysis.

FAQs

Q1: What is the general tolerance limit for titanium medical implants using 5-axis CNC milling machine?

A1: Titanium 5-axis CNC machining usually tolerates tolerances up to ±0.01mm for the non-essential part of the implant and ±0.005mm for the essential parts, along with a surface roughness of Ra ≤ 0.6μm to ensure biocompatibility.

Q2: How does 5-axis CNC machining reduce material waste compared to 3-axis?

A2: There is a 15%-30% increase in material use through 5-axis technology that forms the exact cut by eliminating the excess material allowance for repositioning, moreover, it can take a swing at precious metal medical components due to its nature.

Q3: Can 5-axis CNC machines process biocompatible PEEK plastic?

A3: 5-axis CNC machines allow the processing of PEEK plastic with the incorporation of a very low-temperature cutting system along the production line. It produces a tensile strength of >90MPa, compliant with ISO 10993 for biocompatibility.

Q4: What certifications should a medical CNC supplier have?

A4: Among the ISO 9001, suppliers should also have the ISO 13485 medical quality management system. AS9100D certification is indicative of aerospace-level traceability hence it is suitable for high-risk implant manufacturing.

Q5: How to handle post-processing for 5-axis machined medical parts?

A5: It is advisable to apply electropolishing in place of mechanical polishing for 5-axis machined medical parts in order to remove micro-cracks and achieve a mirror-like finish with Ra 0.2μm. Additionally, the passivation treatment will be effective in augmenting the corrosion resistance of the stainless steel components, thus clinching the aspect of safety in the clinical environment.