Generative AI Helps Robots Jump Higher and Land Safer: MIT’s Breakthrough Design Framework

Designing robots is no small feat it’s a process that typically demands deep technical expertise across motion, materials, and construction

Generative AI Helps Robots Jump Higher and Land Safer: MIT’s Breakthrough Design Framework

Designing robots is no small feat—it’s a process that typically demands deep technical expertise across motion, materials, and construction. Even with advancements in bio-inspired and soft robotics, developing efficient robot hardware still takes time and patience. But now, thanks to generative AI (GenAI) and physics-based simulations, researchers at MIT’s CSAIL (Computer Science and Artificial Intelligence Laboratory) are reshaping how robots are designed, built, and tested.

Blending AI with Human Ingenuity for Robot Design

Traditionally, engineers used sampling-based design methods to iterate robot forms through simulations. These methods are fast and flexible, but they struggle to account for real-world assembly challenges and manufacturing constraints. That’s where MIT's new approach stands out: using diffusion models, a type of generative AI, to refine and enhance human-made designs in a way that works in practice—not just in theory.

With this system, users simply upload a 3D robot design and select the parts they want to improve. GenAI then simulates multiple shape variations to optimize performance. Once the best configuration is identified, the design can be 3D printed immediately, with no further manual adjustments required.

Jumping Robots Just Got Smarter (and Higher)

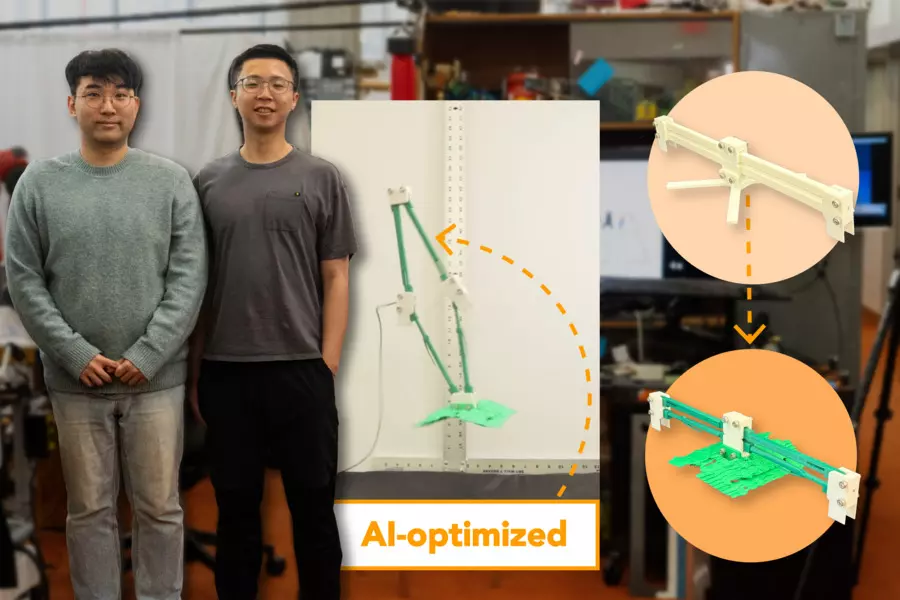

One of the most compelling applications of this tech was creating a tiny jumping robot. MIT researchers compared two versions: one built entirely by humans, and another refined by the diffusion model. Despite being made from the same plastic and following the same basic design, the AI-enhanced version jumped 41% higher—about 2 feet off the ground.

The secret? AI suggested using curved joint structures instead of straight, blocky ones. These subtle changes allowed the robot to store and release energy more effectively without compromising durability.

Using an initial design as a starting point, the AI ran through 500 shape variations over five iterations, eventually honing in on a final, oddly shaped model that proved more efficient in jumping. This new form was then scaled and 3D printed for real-world testing.

Smarter Landings with AI-Optimized Feet

Jumping is just one part of the equation—landing safely is just as crucial. The team turned to GenAI again, this time asking it to design a better robot foot. After multiple simulation cycles, they selected the most stable version. The result? A robot that fell 84% less than its standard counterpart.

This dual improvement in vertical leap and balance highlights how generative AI can optimize both performance and reliability in robotic systems. It’s a promising step forward not just for jumping bots, but for any robot where agility and precision are key.

A Glimpse into the Future of Robot Design

The long-term vision for this technology is even more ambitious. MIT’s Johnson Wang envisions a world where you can describe a robot’s function in plain language—like “make a robot that grabs a coffee mug”—and AI instantly generates a working design.

Byungchul Kim adds that AI could eventually refine how robot parts connect and interact, enabling smarter machines with better movement and task execution. They’re also exploring the addition of extra motors to give robots greater control over direction and landing precision.

The materials currently used are standard 3D-printable plastics, but researchers believe using lighter and stronger materials in the future could further boost robot performance.

With the fusion of generative AI and simulation, MIT is not just making robots smarter—they’re making the process of building them faster, more intuitive, and vastly more effective. From factory floors to future homes, this breakthrough could be a turning point in how robots are imagined and engineered.