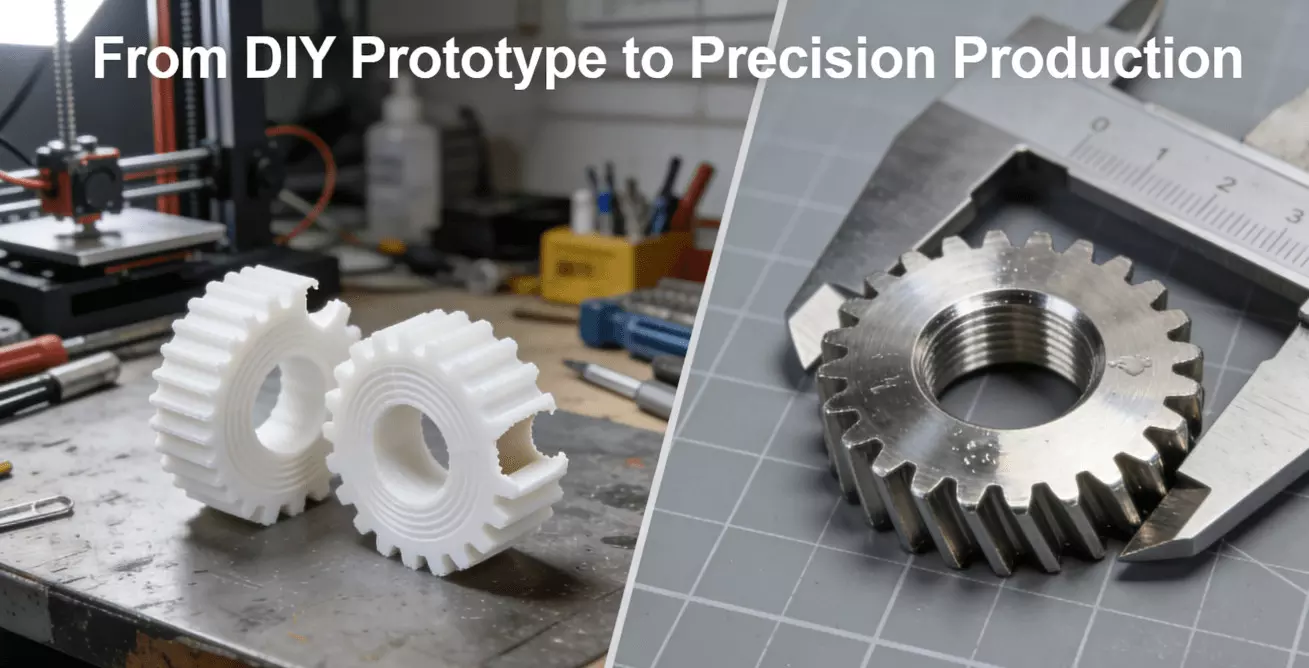

From Prototype to Mass Production: Why 70% of Hardware Entrepreneurs Need to Redesign Their DIY Gear?

Discover why DIY gears fail under real-world conditions. Learn how professional gear hobbing, quality certifications (AS9100D, IATF 16949), and DFM ensure a smooth transition from prototype to high-volume production. Get an expert manufacturing quote.

image for illustrative purpose

Introduction

In the maker and hardware startup fields, using DIY tools to create functional prototypes has become a standard process for validating ideas. However, when a project advances to stages requiring durability, precise transmission, and preparation for mass production, these self-made custom parts, especially gears, often become the weakest link in the system, leading to product test failures and project delays. The root cause lies in the fact that DIY methods typically struggle to meet genuine precision engineering requirements. Material strength, gear tooth profile accuracy, heat treatment processes, and batch consistency are technical thresholds that desktop equipment cannot overcome.

This article will systematically compare the differences between DIY and professional gear manufacturing in terms of materials, processes, accuracy, and scalability, and explain how partnering with precision gear manufacturers possessing certifications like AS9100D can facilitate a smooth transition from prototype gear manufacturing to high volume gear production.

Under what circumstances do DIY-manufactured gears reach their performance limits?

In the rapid prototyping phase, using DIY tools (like FDM 3D printing) for prototype gear manufacturing offers core value in its ability to quickly and cost-effectively validate gear dimensions, basic meshing relationships, and design concepts, making it ideal for design iteration. However, when prototypes need to withstand real-world conditions like continuous load, high speeds, and long-term wear, the performance shortcomings of DIY gears become apparent. 3D-printed plastic gears have far lower strength than metal and are prone to tooth breakage; even DIY metal gears can suffer from internal stresses due to a lack of professional heat treatment, potentially leading to fatigue failure.

According to analysis of gear failure modes by the American Gear Manufacturers Association (AGMA), material fatigue and insufficient manufacturing precision are primary causes of early failures. This highlights the importance of a professional how are gears manufactured process—it requires anticipating these extreme conditions during the design phase through DFM (Design for Manufacturing) principles, thereby enhancing gear reliability from the source and laying a solid foundation for moving from prototype to mass production.

Figure2: Gear hobbing, a high-precision generating process, ensures superior tooth profile consistency and surface finish compared to manual methods.

What core problem does the professional gear manufacturing process "hobbing" solve?

Unlike the "carving" style of DIY or conventional milling, the hobbing process used in professional fields is an efficient "generating method" machining process. The principle of gear hobbing services involves using a tool called a hob that rotates with the gear blank at a constant speed ratio, similar to two gears meshing, to continuously cut the tooth grooves.

This process is a perfect combination of CNC machining and precision engineering, solving four major challenges that DIY methods cannot overcome. The table below provides a clear comparison:

Comparison Dimension | DIY/Conventional Milling | Professional Hobbing Process |

Tooth Profile Consistency | Low, relies on manual operation or low-precision equipment | Extremely high, CNC control ensures identical geometry for each tooth groove |

Surface Finish | Rough, with tool marks, often requires manual polishing | Smooth, high quality directly from forming, reduces wear and noise |

Production Efficiency | Very low, suitable for single pieces | High, enables continuous automated production, suitable for batches |

Material Integrity | Material may be damaged due to improper cutting parameters | Optimized cutting parameters preserve the material's best performance |

Professional gear hobbing services providers utilize advanced CNC machining centers to not only efficiently produce spur gears but also complete complex gears like helical gears and worm wheels in a single, high-precision operation. For teams seeking gear manufacturing guidance, understanding professional hobbing is the first step.

How should the manufacturing path be planned from one sample to ten thousand products?

Successful hardware projects require a clear and scalable manufacturing path. Transitioning from rapid prototyping to high volume gear production requires systematic planning, where custom gear manufacturing services providers play a key role.

Prototype Validation Stage

The core of this stage is "speed" and "accuracy." The goal is to quickly obtain functional samples to validate the design. An excellent supplier should possess fast CNC machining or rapid tooling capabilities and provide DFM feedback to help optimize the design. Prototype gear manufacturing at this stage is key for low-cost trial and error, laying a solid foundation for subsequent phases.

Small-Batch Trial Production Stage

The core of this stage is "stability" and "repeatability." Producing dozens to hundreds of gears for small-batch product testing or market promotion requires the supplier to demonstrate process stability, ensuring consistent quality across batches. The supplier's quality management system (e.g., ISO 9001) becomes important at this stage.

Large-Scale Mass Production Stage

The core of this stage is "cost control" and "absolute reliability." Facing orders for thousands of units, the supplier must possess strong production capacity, supply chain management capabilities, and extreme product consistency.

- Quality System Certification:

Certifications like IATF 16949 (automotive) and AS9100D (aerospace) are the gold standard indicating a supplier's capability for quality control in mass production. These industry-specific certifications require manufacturers to establish traceable systems, strict process controls, and continuous improvement mechanisms, ensuring every part in high volume gear production meets the most stringent specifications, forming the cornerstone of commercial reliability.

- Production Process Optimization:

In the mass production stage, professional manufacturers adopt automated loading/unloading systems, lean production principles to optimize cycle times, and extend tool life through tool management and cutting parameter optimization, achieving significant cost-effectiveness while guaranteeing quality, thereby creating long-term value for customers.

- Supply Chain Transparency:

An excellent manufacturer should provide complete chain information from raw material certificates to final inspection reports. This transparency ensures quick root cause tracing for any deviations during high volume gear production and enables accurate production scheduling, greatly enhancing the predictability of the client's project timeline.

Therefore, choosing a custom gear manufacturing services provider with both rapid prototyping and high volume gear production capabilities ensures a coherent technical path and avoids the risks of re-certification and adaptation associated with switching suppliers.

How to evaluate and select a reliable precision gear manufacturer?

Choosing the right partner is crucial for project success. Here are the core dimensions for evaluating precision gear manufacturers:

Technical Capability and Equipment

Examine the supplier's CNC machining equipment list, process range, and maximum machining accuracy. Requesting case studies of previous custom parts of similar complexity is a direct way to assess their technical strength.

Quality System and Certification

ISO 9001 is the basic threshold. For projects with industry-specific requirements, certifications like IATF 16949 (automotive) or AS9100D (aerospace) are crucial, as they represent the supplier's ability for strict production process control.

Design Support and Communication

An excellent supplier is not just a processor but an engineering partner. They should provide DFM analysis and offer professional advice on material selection, tolerance setting, and cost optimization.

- Document Requirements:

Clarify the file formats they accept (e.g., STEP, PDF). A professional manufacturer should clearly state their required technical document standards.

- Feedback Mechanism:

Understand the response speed for quotations and design feedback. Excellent precision gear manufacturers typically have dedicated application engineer teams capable of providing initial feedback including DFM analysis within 24-48 hours of receiving an inquiry, pointing out potential issues in the design affecting cost, lifespan, or manufacturability. This proactive communication is a key indicator of their service level.

- Project Management:

Check if there is a dedicated project manager to ensure smooth communication. From project initiation to delivery, a single point of contact ensures efficient and accurate transfer of all technical requirements, progress updates, and change requests, which is crucial for complex custom gear manufacturing services projects and significantly reduces communication costs and management risks.

According to the Manufacturers Alliance for Productivity and Innovation (MAPI), choosing a manufacturer with rigorous quality processes is crucial for the long-term success of a product and supply chain resilience.

What hidden benefits can partnering with a professional manufacturer bring to a hardware startup project?

Partnering with a professional custom gear manufacturing services provider offers value far beyond simply "making parts." The hidden benefits it brings are multipliers for project success.

The most significant benefit is risk reduction. The experience of precision engineering experts helps avoid design pitfalls early on, and the material certifications and test reports they provide also serve as solid evidence for dealing with investors and clients. Secondly, the time value: more accurate delivery predictions and stable quality make project scheduling more reliable, accelerating time to market.

More importantly, it liberates the core innovation capability of the startup team. The team doesn't need to become gear experts and can focus their energy on product definition, software development, and market expansion. For example, a comprehensive gear machining service provider will intervene from the design end to ensure the optimal solution; this kind of precision engineering support is invaluable.

These value-added benefits based on professional knowledge can significantly reduce overall project risk and ultimately lower the total cost of ownership through optimized designs and avoided rework.

Conclusion

Moving from a DIY prototype to a reliable product, the choice of gear manufacturing method is a critical engineering decision point. Understanding the process depth, quality systems, and scaling capabilities of professional gear manufacturing is the bridge for hardware projects to cross the chasm between "creatively feasible" and "commercially reliable." Leveraging the expertise of precision gear manufacturers is not just about purchasing parts, but also about buying risk reduction and time value.

If you are pushing your project to the next, more demanding stage, it is recommended to take immediate action: directly request a Design for Manufacturability (DFM) analysis quote for your existing design from a professional supplier with certifications like ISO 14001 and AS9100D, such as LS Manufacturing. This is usually the first step towards a successful partnership.

Author Bio

This article was contributed by an engineer with over 15 years of experience in the precision manufacturing field. He has a deep understanding of the manufacturing challenges from rapid prototyping to mass production and is currently employed by a Chinese precision manufacturing company certified to ISO 9001, IATF 16949, and AS9100D.

FAQs

Q1: How many gear prototypes do I need before considering a professional manufacturer?

A: There is no fixed number. The best time is when your design is basically finalized, and you need to test material performance, real-world lifespan, or prepare for small-scale trial production. Even if only 1-2 samples are needed for rigorous testing, professional manufacturing can provide decisive data.

Q2: What is the typical lead time for professional gear manufacturing?

A: For prototypes, complex gears typically take 2-4 weeks, including material procurement, programming, and inspection. Lead times for mass production depend on quantity, and the supplier should provide a detailed schedule. Choosing local US manufacturing services can significantly shorten logistics and communication time.

Q3: Besides metal, what other materials can be used to make gears?

A: Absolutely. In addition to various steels and aluminum alloys, professional manufacturers commonly use engineering plastics (such as nylon, POM), brass, and even composite materials. Material selection depends on load, noise, corrosion resistance, and cost requirements.

Q4: Does "custom gear" mean exorbitant mold costs?

A: Not necessarily. For many specifications, using CNC machining or hobbing services allows direct machining from bar stock or blanks, avoiding expensive dedicated molds. This is very suitable for small batches and custom gear manufacturing services, greatly reducing the entry cost.

Q5: How do I provide my gear design to the manufacturer?

A: Providing complete 2D engineering drawings (PDF/DWG) is a standard requirement, with dimensions, tolerances, materials, and technical requirements clearly marked on the drawings. Simultaneously providing a 3D model (STEP or IGES files) will greatly assist programming and communication, ensuring mutual understanding.