The Rise of Paper: Exploring Paper Cup, Plate, Bowl, and Glass Machines

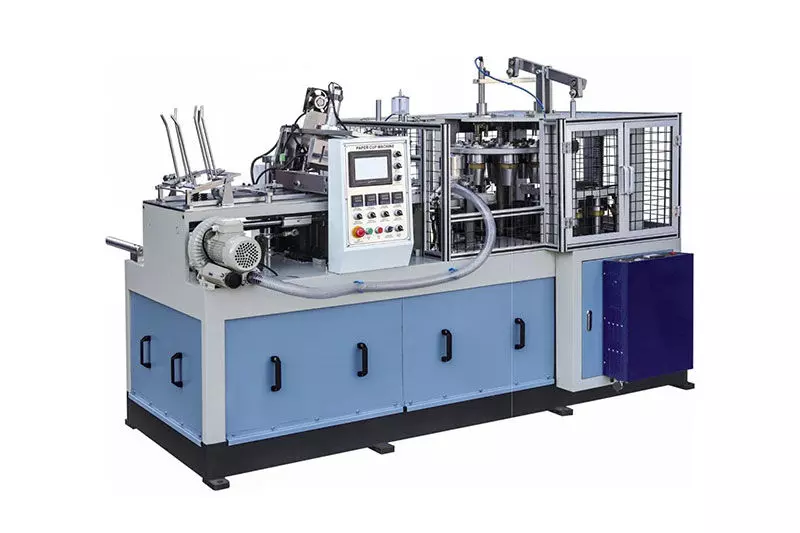

image for illustrative purpose

In an era where sustainability is no longer just a buzzword but a necessity, the disposable tableware industry is undergoing a significant transformation. As the world shifts away from single-use plastics, paper-based alternatives are gaining momentum. Central to this revolution are the machines that manufacture paper cups, plates, bowls, and glasses. These machines are at the forefront of the eco-friendly movement, combining technology and environmental consciousness to create products that meet modern-day demands. Let's dive into the world of paper tableware machines and understand their impact on the industry and the environment.

The Need for Paper-Based Alternatives

The detrimental effects of plastic pollution are well-documented. From oceans to landfills, plastic waste poses a severe threat to wildlife, ecosystems, and human health. Governments and organizations worldwide are implementing bans and restrictions on single-use plastics, spurring the need for sustainable alternatives. Paper-based products, which are biodegradable and often compostable, have emerged as a viable solution. The transition to paper requires efficient and advanced machinery capable of producing high-quality products at scale.

Paper Cup Machines

Paper cup machines are designed to produce a range of cup sizes, suitable for both hot and cold beverages. The manufacturing process involves several steps:

Paper Feeding: High-quality paper rolls are fed into the machine.

Side Sealing: The paper is formed into a cylindrical shape, and the sides are sealed using heat or ultrasonic technology.

Bottom Sealing: The bottom of the cup is added and sealed to ensure it is leak-proof.

Curling: The rim of the cup is curled for user comfort and added strength.

Modern paper cup machines are highly automated, ensuring precision and efficiency. They are capable of producing thousands of cups per hour, making them essential for meeting the high demand from coffee shops, fast food chains, and other food service providers.

Paper Plate Machines

Paper plate machines are versatile, capable of producing plates of various sizes and shapes. The process includes:

Raw Material Feeding: Paper rolls or sheets are fed into the machine.

Forming: The paper is pressed and shaped into plates using molds and dies.

Cutting: Excess paper is trimmed to ensure a clean edge.

Stacking: Finished plates are automatically stacked for packaging.

These machines are equipped with advanced control systems for precise operation and minimal waste. They can handle different types of paper, including coated and uncoated varieties, to produce plates that are sturdy and durable.

Paper Bowl Machines

Paper bowl machines are similar to paper cup machines but are specifically designed to handle the deeper shape of bowls. The key steps in the manufacturing process are:

Feeding: Paper material is fed into the machine.

Forming and Sealing: The paper is formed into a bowl shape, and the sides and bottom are sealed.

Rim Curling: The rim is curled to enhance strength and user comfort.

Output: Finished bowls are ejected and stacked.

These machines are essential for producing bowls used for soups, salads, and other foods that require a more substantial container than a plate.

Paper Glass Machines

Paper glass machines produce disposable glasses used for beverages, similar to paper cups but often with a more elegant design suitable for parties and events. The process includes:

Material Feeding: High-quality paper rolls are fed into the machine.

Forming and Sealing: The paper is formed into a glass shape and sealed.

Reinforcement: Additional layers or coatings are applied for strength and waterproofing.

Finishing: The rims are finished, and the glasses are stacked.

Advantages of Modern Paper Tableware Machines

Eco-Friendly Production: These machines facilitate the production of biodegradable and compostable products, reducing environmental impact.

High Efficiency: Automation and advanced technologies ensure high production rates and consistent quality.

Versatility: Capable of producing a wide range of products in different sizes and designs.

Cost-Effective: Reduces reliance on manual labor and minimizes waste, resulting in cost savings.

The Future of Disposable Tableware

As technology advances and environmental awareness grows, the demand for sustainable tableware will continue to rise. The development of innovative paper-based products and improvements in manufacturing processes will play a crucial role in this transition. Investment in paper cup, plate, bowl, and glass machines is an investment in a greener future.

Conclusion

The shift towards paper-based disposable tableware is more than just a trend; it's a movement towards sustainability and responsible consumption. Paper cup, plate, bowl, and glass machines are the unsung heroes of this movement, enabling the production of eco-friendly alternatives to plastic. As we continue to innovate and embrace these technologies, we move closer to a world where convenience doesn't come at the cost of our planet.