Bridging Discovery and Development: Why Integrated Models Reduce Drug Attrition

image for illustrative purpose

Drug discovery involves high risk, with large amounts of time and money depending on whether a single drug candidate succeeds. Failure rates are still very high. Studies estimate that close to 90 percent of drug candidates fail between early research to clinical approval. Common reasons include poor drug behavior in the body, safety issues, weak results, or problems making the drug at scale.

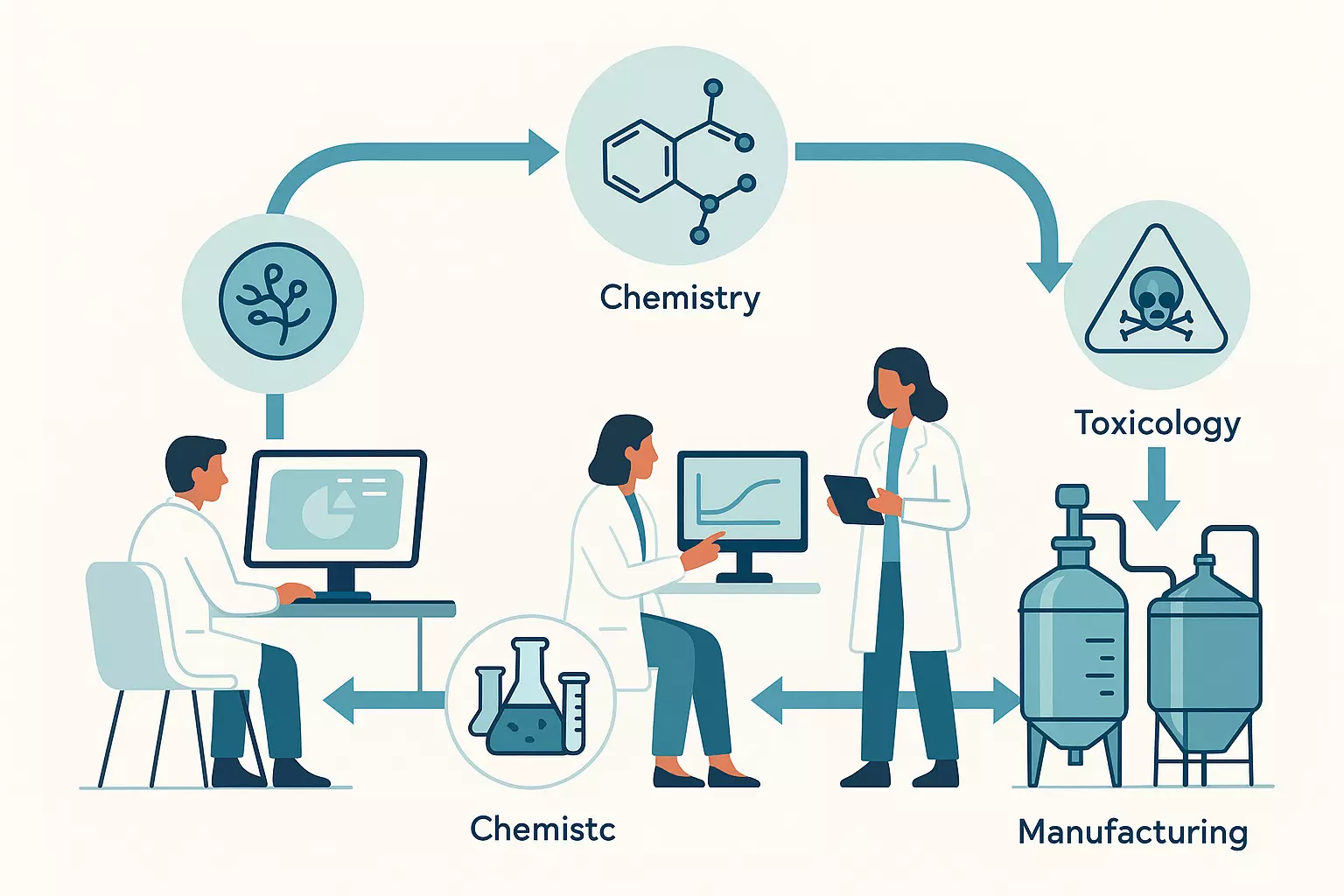

To address these issues, some parts of the industry are using integrated models that link early research with later development. In this setup, groups such as a CRDMO bring biology, chemistry, DMPK, toxicology, and manufacturing together in one place. The goal is to spot problems earlier and reduce the chance of failure later in development.

Why Drug Candidates Fail

Many failures happen because discovery and development are handled separately. A compound may work well in early lab tests but fail later during scale up or clinical studies.

This often happens because key risks were not checked early enough.

Common gaps include:

- Incomplete early data

Limited ADME or DMPK data can lead to poor drug exposure in humans.

- Late safety findings

Toxicity issues found late in development can stop a program after large costs.

- Manufacturing problems

Some compounds are hard to make at a larger scale or lack process stability.

These gaps show why stronger links between discovery and development are needed. Many organizations using an integrated drug discovery framework benefit from a single, connected path from target validation to clinical readiness, which helps teams work more efficiently and improve methods at each stage of development.

Integrated Models and How They Help

An integrated model brings teams together from the start. Discovery and development steps move forward at the same time instead of one after another.

This allows teams to share data early and adjust plans faster.

Key benefits include:

- Connected data

Biology, chemistry, and DMPK results are reviewed together, which helps reduce blind spots. - Fewer handovers

Working within one organization reduces delays and errors that can happen between vendors. - Early focus on scale up

Manufacturing limits are identified earlier, which lowers the risk of later reformulation.

This approach improves the chance that a lab discovery can move forward into clinical testing.

Connecting Biology and Chemistry

Drug discovery depends on close work between biology and chemistry.

- Biology teams study disease pathways and confirm drug targets.

- Chemistry teams design molecules that act on those targets.

- Early teamwork helps ensure compounds are not only active in tests but also suitable for further development.

This reduces the risk of spending time on compounds that cannot progress.

The Role of DMPK and Toxicology

Pharmacokinetics and toxicology are major reasons drugs fail.

In integrated models, these studies begin early during discovery.

This allows teams to:

- Estimate absorption, distribution, metabolism, and excretion.

- Check for possible drug drug interactions.

- Look for safety risks before large investments.

Early data helps teams focus on candidates with better safety and exposure profiles.

Manufacturing and Scale Up

A drug must be practical to make. If it cannot be produced reliably, it cannot move forward.

Integrated models involve manufacturing experts early to review:

- Synthetic routes

- Scale up feasibility

- Formulation stability

In a CRDMO setup, process chemistry and manufacturing plans are considered alongside discovery work. This helps reduce delays later.

Regulatory Considerations

Regulatory review depends on clear and linked data from early studies through production.

Integrated models help create data packages that connect safety, efficacy, and quality.

This can make regulatory review clearer and more consistent.

Observed Outcomes From Integrated Approaches

Some companies report shorter timelines and fewer failures when using integrated discovery and development models.

Examples often include earlier identification of DMPK risks and fewer manufacturing changes later in development.

The reported results include lower costs, fewer late stage failures, and faster progress to clinical testing.

Summary

Drug development failure remains a major issue in biopharma. Integrated working models offer a way to address this problem. By linking discovery and development activities, teams can spot risks earlier and make better choices.

Working with a CRDMO brings together biology, chemistry, DMPK, toxicology, and manufacturing under one collaborative framework. This reduces fragmentation and supports data driven decisions.

These models aim to shorten development timelines and improve reliability. Most importantly, they help move safe and effective therapies to patients more efficiently.