FR-4 TG170: High-Temperature PCB Material for Advanced Electronics

FR-4 TG170 is a high-performance PCB material designed for high-temperature and high-stress applications. Learn its properties, benefits, and uses.

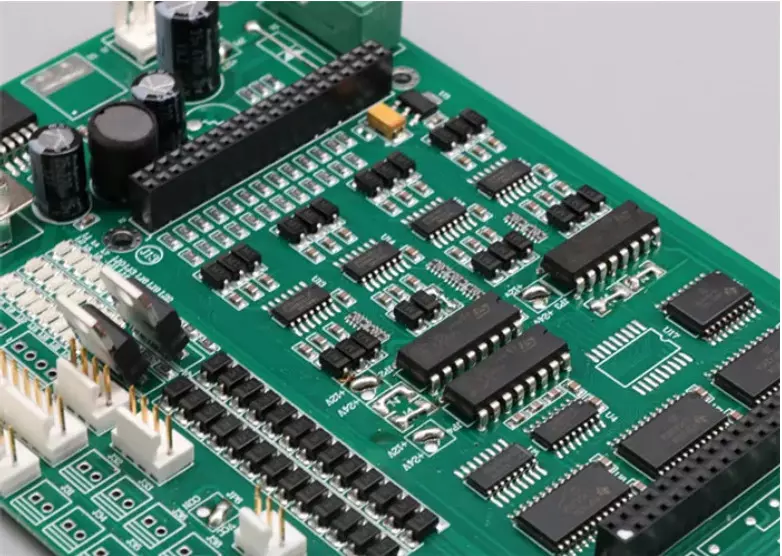

image for illustrative purpose

Printed circuit boards (PCBs) are vital elements in the modern electronics industry, enabling circuits on devices such as the common devices to the industrial systems and aerospace. FR-4 TG170 is one of the high-performance PCB materials that is known to be very stable in thermal performance, mechanical strength and long-term reliability. The knowledge of FR-4 TG170, its characteristics and usages are paramount to engineers and designers choosing material to use in a high-temperature and demanding electronic system.

What is FR-4 TG170?

FR-4 TG170 is a flame-retardant, glass-reinforced, epoxy laminate that is designed to stand extra-high temperatures in comparison to a normal FR-4 or FR-4 TG150. The Tg means the glass transition temperature and the 170 means that the Tg is around 170C. This large Tg guarantees that FR-4 TG170 does not lose its mechanical strength or structural integrity in the high thermal environment and is therefore suitable in high stress electronics.

One of the important factors of PCB performance is the glass transition temperature. At temperatures below Tg, FR-4 TG170 is rigid, which guarantees constant electrical and mechanical performance. The material becomes soft at temperatures close to or beyond Tg, and this may interfere with board performance. The FR-4 TG170 offered by designers will keep their PCBs straight even under high-temperature conditions.

Key Properties of FR-4 TG170

FR-4 TG170 is appreciated due to the combination of thermal, mechanical and electrical properties. The most salient features are:

High Thermal Resistance: FR-4 TG170 can be subjected to constant temperatures of up to 170 o C without deforming. This renders it to be appropriate in automotive electronics, industrial equipment and power electronics.

Mechanical Strength: FR-4 TG170 is reinforced with fiberglass, which makes it have a high rigidity and dimensional stability, being free of bending, cracking and delamination.

Flame Retardancy: FR-4 TG170 is flame-retardant just like any FR-4 material, and is therefore safe in a consumer and industrial device.

Chemical Protection: Epoxy matrix helps to protect FR-4 TG170 against moisture, solvents, and other chemicals which increases the longevity of the material in the adverse environment.

Electrical Stability: FR-4 TG170 has a stable dielectric property and can support sensitive and high-speed circuits even in high temperatures.

Advantages of FR-4 TG170

FR-4 TG170 is a better choice than standard FR-4 and medium Tg materials because it has several advantages:

Increased Heat Budget: FR-4 TG170 has a higher Tg which means that it can be used in high-temperature applications in the automotive under-hood and in industrial electronics and systems.

Better Reliability: FR-4 TG170 is dimensionally stable even in the case of thermal cycling and lowers the chances of warping, delamination, and mechanical breakdown.

Lead-Free Soldering Compatibility: New lead-free soldering methods demand boards capable of operating at peak temperatures of approximately 260 o C. Due to the thermal properties of FR-4 TG170, it can be applied in these processes.

Long-Term Durability: The thermal, chemical, and mechanical resistance of FR-4 TG170 make it retain its functions in the long-term.

Applications in High Stress Systems FR-4 TG170 can be used with mechanical stress, vibration and repeated temperature systems and so can be applied to aerospace, defense and high-power electronics.

FR-4 TG170 vs Other FR-4 Grades

The chief difference between FR-4 TG170 and other FR-4 materials is glass transition temperature:

Normal FR-4: Tg =130-140 C, can be used in low to moderate temperature.

FR-4 TG150: Tg =150 ° C, has improved thermal resistance in moderate heat applications.

FR-4 TG170: Tg -170 C, suitable in high temperature and high stress environments.

FR-4 TG170 is more costly than lower-Tg boards, but the thermal stability and reliability of the material is needed in the applications where regular materials would fail.

Applications of FR-4 TG170

FR-4 TG170 is generally applied in the industry and application where thermal resistance and long-term performance are of great importance:

1. Automotive Electronics

The contemporary cars are highly dependent on the electronics in controlling the engine, infotainment systems, and safety systems. FR-4 TG170 is a type of PCB that guarantees stability of the PCBs in electronic control units (ECU) and sensor modules when operating in high engine temperatures and vibrations.

2. Industrial Control Systems

Power electronics, motor controllers and industrial automation systems produce a lot of heat when in operation. FR-4 TG170 is the mechanical strength and thermal resistance that is needed to ensure performance and reliability.

3. LED Drivers and Power Electronics.

The devices which operate at high-current and power levels, e.g., LED drivers, may heat up. FR-4 TG170 has the ability to handle these devices to avoid early failure because of heat or stress.

4. Telecommunications Equipment

Base stations, communication hardware and networking devices are frequently exposed to a wide range of temperatures. FR-4 TG170 would guarantee the reliable operation of these systems as well as mitigate the possibility of failure.

5. Electronics in aerospace and defense.

Aerospace and defense electronics are subjected to severe conditions such as thermal cycling, vibration as well as mechanical stress. FR-4 TG170 offers the required stability, reliability and durability of mission critical components.

FR-4 TG170 Your PCB Design of Choice

In selecting FR-4 TG170 to use in a project, the following factors should be taken into consideration:

Operating Temperature Range: It is important to make sure that the Tg of the material is higher than the maximum operating temperature by at least 2030 o C.

Thermal Cycling: FR-4 TG170 is used where frequent heating and cooling are required.

Mechanical Stress: FR-4 TG170 reinforced fiberglass structure is an advantage in the high-stress environment.

Cost: FR-4 TG170 is more expensive than standard FR-4 although it offers long-term reliability which makes the investment worthwhile.

Assembly Requirements: FR-4 TG170 is resistant to high temperature assembly processes including lead-free assembly.

Conclusion

FR-4 TG170 is a high-performance PCB material, which is developed in high temperature, high stress, and long run, reliability use. It has great mechanical stability, a high glass transition temperature and a high resistance to many chemicals, which have seen it being a prime candidate in the automotive, industrial, power electronics, telecommunications, aerospace and defense industries.

Using FR-4 TG170, engineers can be confident in the performance of their PCBs in the most severe conditions, which will guarantee the functionality and durability of the latest electronic equipment. FR-4 TG170 is still the preferred material in high-performance applications in which thermal and mechanical reliability is extremely important.