Silicone Products Manufacturer – Innovative Solutions for Modern Industries

image for illustrative purpose

Introduction to Silicone Product Manufacturing

Silicone products have become essential in multiple industries due to their flexibility, temperature resistance, and adaptability. A silicone products manufacturer focuses on creating precision-molded parts that meet the needs of medical, automotive, food-grade, and consumer sectors. These manufacturers combine advanced materials and engineering to deliver high-performance silicone components.

What Makes Silicone an Ideal Material

Silicone offers versatility that other polymers cannot match. It performs well under extreme temperature ranges and maintains its form and elasticity even in challenging environments. Manufacturers prefer silicone because it can be molded into complex shapes while maintaining dimensional accuracy.

Key Advantages of Silicone Material

- High resistance to heat and chemicals

- Excellent electrical insulation properties

- Flexibility across wide temperature variations

- Low compression set for reliable performance

The Role of a Silicone Products Manufacturer

A silicone products manufacturer handles the complete process — from design and prototyping to mass production. They work closely with clients to meet exact specifications, ensuring each part fits its intended use. The focus is on precision, consistency, and customization for different market sectors.

Core Capabilities of Manufacturers

- Compression molding for simple shapes and cost-effective production

- Liquid Silicone Rubber (LSR) injection molding for complex geometries and high-volume orders

- Extrusion for continuous silicone tubing and profiles

- Overmolding for bonding silicone with plastic or metal components

Custom Silicone Products for Specialized Applications

Every industry has unique product requirements. That’s why custom silicone products have gained importance. Manufacturers design and produce components tailored to specific performance, design, and color needs.

Examples of Custom Silicone Products

- Medical seals, valves, and tubing

- Silicone gaskets and keypads for electronics

- Food-grade silicone molds and kitchenware

- Automotive seals and vibration control components

- Custom silicone wearable and smart device parts

The Process of Manufacturing Custom Silicone Parts

Creating custom silicone parts involves several precise steps that ensure accuracy and consistency.

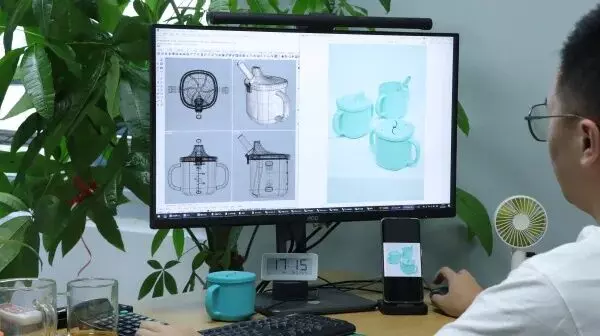

Step 1: Product Design and Engineering

Manufacturers use CAD models to design silicone parts according to specific requirements. Each design is optimized for moldability, thickness, and functionality.

Step 2: Material Selection

Depending on the use case, different silicone grades are chosen — medical-grade, food-grade, or industrial-grade. Each type offers performance characteristics suitable for its environment.

Step 3: Mold Fabrication and Prototyping

Molds are created using CNC machining or EDM technology. Prototyping ensures the design meets all dimensional and functional goals before full-scale production.

Step 4: Production and Quality Testing

Once approved, production begins using compression or injection molding. Every batch undergoes visual and mechanical testing to verify performance standards.

Industries Served by Silicone Product Manufacturers

A reputable silicone products manufacturer supplies components to a wide range of industries.

Medical and Healthcare Sector

Medical-grade silicone parts are used in devices such as catheters, syringes, and respiratory equipment. Silicone’s biocompatibility and resistance to sterilization make it ideal for healthcare applications.

Automotive and Aerospace

In these industries, silicone is used for gaskets, seals, and connectors that withstand high temperatures and pressure variations.

Food and Beverage

Food-grade silicone molds, seals, and tubes are common in food processing, packaging, and kitchen appliances.

Consumer Electronics

Silicone is used in keypads, switches, protective covers, and wearables due to its flexibility and resilience.

Silicone Injection Molding Technology

Many manufacturers rely on Liquid Silicone Rubber (LSR) injection molding to produce high-quality components. This process enables automated, repeatable production with tight tolerances.

- Benefits of LSR Injection Molding

- Precision molding for intricate designs

- High-volume capability with minimal waste

- Enhanced consistency across production runs

- Compatibility with overmolding applications

Quality Control in Silicone Manufacturing

Quality is critical in silicone production. Manufacturers implement strict inspection procedures to ensure each part meets required standards.

Common Quality Control Techniques

- Dimensional checks with optical measurement systems

- Tensile and compression testing

- Surface finish and visual inspections

- Compliance with FDA, ISO, and RoHS standards

Choosing the Right Silicone Products Manufacturer

When selecting a silicone manufacturer, businesses should consider technical expertise, manufacturing capability, and customization options.

Factors to Evaluate

- Experience in multi-industry silicone production

- Access to advanced molding technologies

- Support for prototyping and design development

- Ability to provide custom silicone formulations

The Future of Silicone Product Manufacturing

The silicone industry continues to evolve with automation, material innovation, and eco-friendly practices. Manufacturers are developing recyclable silicone blends and integrating digital monitoring systems to optimize production.

Trends Driving Innovation

Smart silicone materials with conductive properties

Medical-grade silicone for wearable technology

High-precision micro-molding for compact devices

Sustainable silicone production using green energy

Conclusion

A silicone products manufacturer plays a crucial role in producing parts that support technological growth and industrial innovation. With expertise in molding, material selection, and customization, these manufacturers create custom silicone products that serve diverse sectors — from healthcare to electronics. As industries advance, silicone continues to be the material of choice for performance-driven solutions.